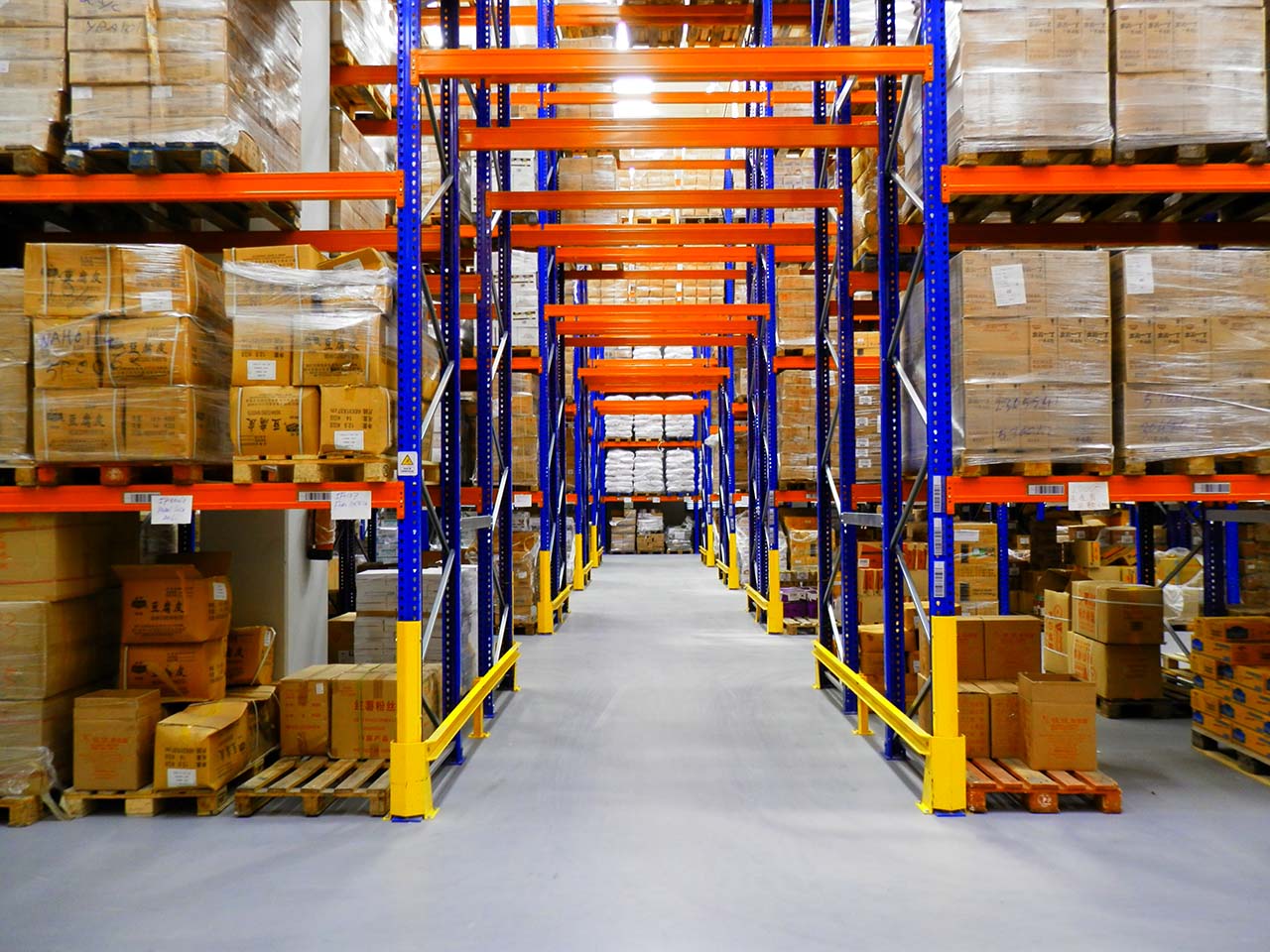

Introduction: Efficient warehouse storage requires strategic utilization of racking rack solutions.

These systems play a vital role in maximizing storage capacity and optimizing inventory management.

In this article, we will explore the benefits of choosing the right racking rack for your warehouse and delve into the different types available in the market.

The Importance of Racking Racks Limited storage space poses a challenge for warehouses, but the use of racking racks can significantly enhance storage efficiency.

By utilizing these racks, warehouses can efficiently organize their inventory, streamline operations, and improve overall productivity.

Types of Racking Racks for Different Storage Needs Warehouses have diverse storage requirements, and there are various types of racking racks to address these needs.

Pallet racks are a popular choice, offering easy accessibility and flexibility for storing items in bulk.

Cantilever racks are ideal for accommodating long and bulky items such as pipes or lumber.

Drive-in racks are designed for high-density storage, allowing warehouses to make the most of their available space.

Push-back racks provide a balance between selectivity and storage density, enabling efficient inventory rotation.

Additionally, mezzanine racks offer a practical solution to create additional storage areas without expanding the warehouse's footprint.

Factors to Consider When Choosing Racking Racks Selecting the right racking racks requires careful consideration of several factors.

Warehouses must evaluate their available space to determine the most suitable racking rack options.

Assessing the weight capacity needed for different inventory items is essential to ensure safe and secure storage.

Accessibility and selectivity are crucial considerations, as different types of racking racks offer varying levels of accessibility and selectivity.

Safety and durability should also be prioritized, as robust racking systems protect personnel and maintain the integrity of stored items.

Best Practices for Racking Rack Installation and Maintenance Proper installation of racking racks is crucial for their effectiveness and stability.

It is recommended to follow manufacturer guidelines and seek professional assistance when needed.

Regular inspections are essential to identify any potential issues or damage to the racks and address them promptly.

Maintenance practices, including routine cleaning, repairs, and component replacements, contribute to the longevity and optimal performance of the racking system.

Conclusion: Investing in the right racking rack solutions is a key strategy for enhancing storage efficiency in warehouses.

By carefully considering storage needs, exploring the various types of racking racks available, and implementing best practices for installation and maintenance, warehouses can maximize their storage capacity and improve operational workflows. Choose the right racking rack solutions and unlock the full potential of your warehouse's storage space.

In this article, we will explore the benefits of choosing the right racking rack for your warehouse and delve into the different types available in the market.

The Importance of Racking Racks Limited storage space poses a challenge for warehouses, but the use of racking racks can significantly enhance storage efficiency.

By utilizing these racks, warehouses can efficiently organize their inventory, streamline operations, and improve overall productivity.

In this article, we will explore the benefits of choosing the right racking rack for your warehouse and delve into the different types available in the market.

The Importance of Racking Racks Limited storage space poses a challenge for warehouses, but the use of racking racks can significantly enhance storage efficiency.

By utilizing these racks, warehouses can efficiently organize their inventory, streamline operations, and improve overall productivity.